WATER-COOLED EQUIPMENT FOR STEEL MELTING AND REFINING FURNACES.

We manufacture specialized equipment for steel mills and other industries, providing customized and innovative solutions.

From design, engineering, to equipment manufacturing for the general industry, with a focus on steel mills.

Improve your efficiency and productivity with our consulting and training in steel production plants.

Ensure the successful start-up of your plant with our specialized solutions and guidance.

We started operations in 1994, with the following lines of business or activities:

Technical Consultancy in the field of steel manufacturing, for the process and fabrication of Steel Mill Equipment.

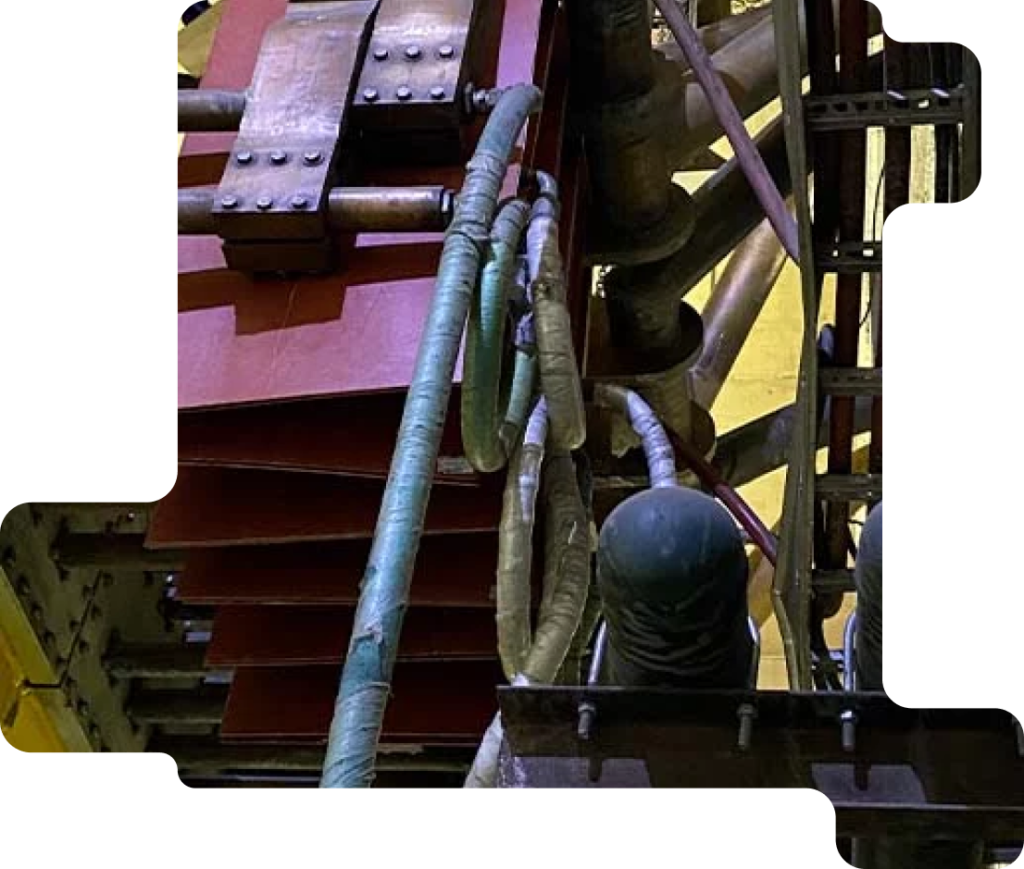

Manufacturing of water-cooled parts for steel manufacturing furnaces.

Subsequently, we ventured into the manufacturing of melting furnaces, heat treatment equipment, heat exchangers, dust collectors, material handling equipment, etc. All designed for electric steel mills with Arc and Induction Furnaces."

WATER-COOLED EQUIPMENT FOR STEEL MELTING AND REFINING FURNACES.

SPECIALIZED EQUIPMENT AND MACHINERY FOR REFRACTORY INSTALLATIONS, FERROALLOYS, AND SLAG PREPARATION.

DESIGN OF SYNTHETIC SLAGS TO OPTIMIZE STEEL PRODUCTION PROCESSES.

HUMAN AND TECHNICAL RESOURCES FOR THE INSTALLATION AND START-UP OF STEEL MILLS.

CONSULTING AND ADVISORY SERVICES TO SOLVE QUALITY, QUANTITY, AND/OR PROCESS OPTIMIZATION ISSUES IN STEEL MANUFACTURING.

We offer over 30 years of experience in operating and manufacturing steel for various specializations and applications, including:

With the activities carried out in steel plants, the company has ventured into the design, manufacturing, and installation of other industrial equipment for special or specific applications, such as:

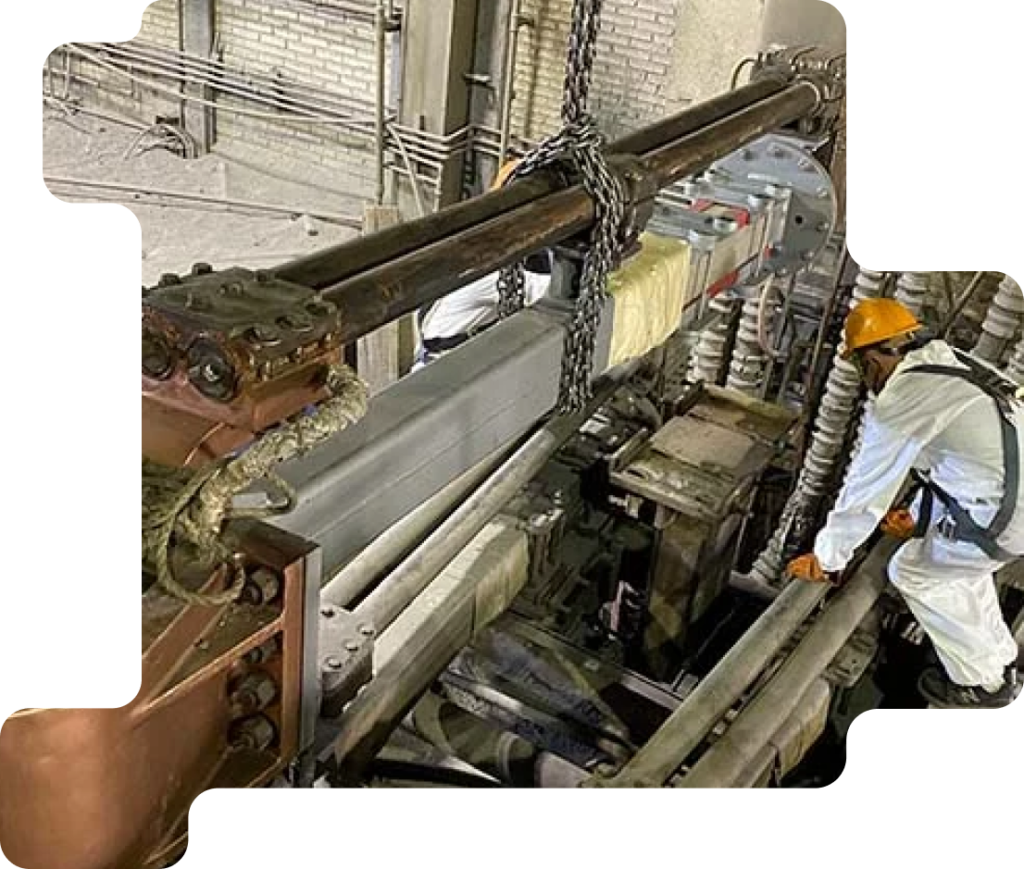

Repair of Copper Parts for Transformers, Secondary Buses for Electric Arc Furnace Arms.

Among the services our company offers to the general industry are:

More than 30 years of experience in the industry and a highly trained team to provide customized and innovative solutions.

For something to endure, it must be done correctly. Our commitment to quality is non-negotiable.

Once you work with us, you will have our team always ready to address your needs.

Leaders in innovative metallurgical solutions. From cooling technologies and specialized equipment to material design and metallurgical consultancy.

Leave us your number, and we will contact you.